About

Prefabricated PV-Storage-DC Flexible Super Charging Station

The Prefabricated PV-Storage-DC Flexible Super Charging Station system is a rapid deployment charging solution composed of a photovoltaic power generation system, energy storage system, charger (pile) equipment, and a DC system. Against the backdrop of a surge in new energy vehicle ownership, the prefabricated structure facilitates accelerated deployment across multiple scenarios, meets the destination charging needs of new energy vehicles, and achieves green construction requirements for land saving, energy saving, material saving, water saving, and environmental protection.

The Prefabricated PV-Storage-DC Flexible Super Charging Station system belongs to the category: Key Energy-saving Technology/Equipment (Product). Suitable for various urban environments, it solves the problems of low efficiency and long construction cycles of traditional charging stations.

Technical Principle

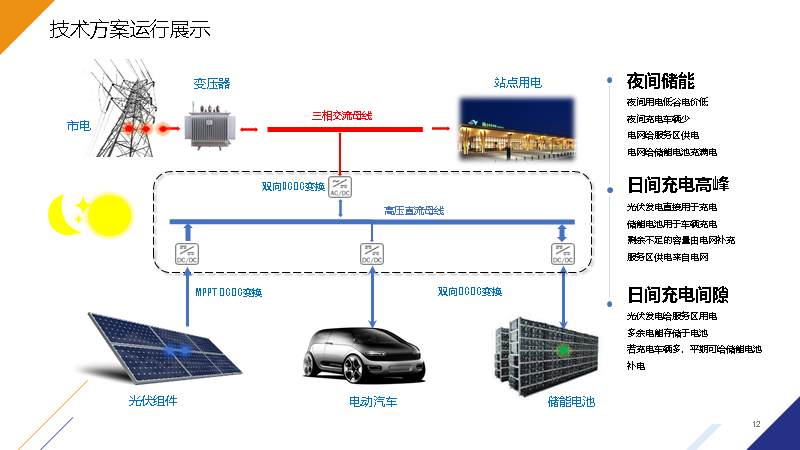

The system access method allows the host unit to be placed as close as possible to the charging piles. The energy of one DC charging host can be optimally dispatched to each charging pile, minimizing DC power consumption and maximizing the output current of the charger.

Scope of Application

Suitable for rocky hard ground, cement hard ground (asphalt hard ground), medium-hard soil, and medium-soft soil ground. Can be rapidly deployed in urban commercial centers, government office buildings, residential areas, etc.

System Advantages

Modular design, prefabricated structure, rapid deployment, short construction period (approx. 5 days).

Reduces on-site construction, lowers noise, prevents dust, reduces environmental pollution, clean transportation.

Saves resources such as water, electricity, and materials, adhering to sustainable development principles.

The prefabricated PV-Storage-Charging-DC-Flexible system consists of photovoltaic power generation, energy storage system, and charger (pile) equipment, connected via a "T" junction to the DC busbar as the confluence system.

Core Components

Solar PV Carport: Length 7500mm, installed with solar PV panels.

Charging Piles: Configured with two types: one pile with two guns (0~40kW) and one pile with one gun (0~40kW).

Energy Storage System: Uses lithium-ion batteries to store excess solar energy or off-peak grid electricity.

Construction Process

R&D and Design Phase: Select design plan based on the project location, configure Hailiang V2.0 solution.

Production, Assembly, and Debugging Phase: Complete production, assembly, and inspection of the charging station system in the factory.

On-site Installation and Configuration Phase: Level and prepare the site, complete power point and grounding grid setup, deploy the prefabricated system.

Patent Technology

Multi-objective DC flexible charging management method and device based on PV-Storage-Charging-Discharging (Patent No.: 2023112318137)

Charging management method, device, equipment, and medium based on microgrid access control (Patent No.: 2023111179461)

PV Wing- déployable Containerized Mobile PV-Storage-DC Flexible Super Charging Station (Patent No.: 2023105232502, under substantive examination)

Basic composition of the prefabricated PV-Storage-Charging system: Charger (pile) and power stack, prefabricated substation, system energy storage, system photovoltaics, charging pile foundation base, etc.

System Process

Charging station construction is first produced and fully configured in the factory according to typical plans.

On-site construction workload is minimal, mainly involving site leveling and reinforcement work.

Overall on-site work content is completed within approximately 3~5 days.

Technology Comparison

Conventional Charging Station: Long construction period (at least 30 days), construction occupies 2/3 of the time, significant impact on the surrounding environment.

Prefabricated Charging Station: Short construction period (approx. 5 days), factory prefabrication, rapid on-site installation, minimal environmental impact.

Certification Status

Selected into the second batch of National (Shenzhen) Climate Investment and Financing Project Library.

Selected into the Shenzhen Green and Low-Carbon Technology, Equipment (Product) Promotion Catalog (2023 Edition).

Obtained multiple software copyrights, including EMC New Energy Commercial Vehicle Operation Supervision and Intelligent Maintenance Platform.

Several typical cases have been implemented in Futian District, demonstrating the practical benefits and application value of the Prefabricated PV-Storage-DC Flexible Super Charging Station system.

Nongke·Times Technology Building Project

Occupies approximately 1000㎡ of vacant land, installing the prefabricated PV-Storage-DC Flexible Super Charging Station system on the original 52 parking spaces.

Project investment of 2 million RMB, annual energy saving capacity of 7.42 tce, annual carbon reduction capacity of 272.5 tCO2.

Utilized existing low-voltage cabinets for modification, configured with a 200kWh battery cabinet and PV carport system.

Futian Transport Hub Bus Terminal Project

Occupies approximately 1400㎡ of vacant land, installing the system on the original 16 bus parking spaces.

Project investment of 4.5 million RMB, annual energy saving capacity of 3.44 tce, annual carbon reduction capacity of 12.63 tCO2.

Requires a new 1*800kVA transformer, serving new energy vehicles for charging.

Comprehensive Benefits

Economic Benefits: Investment payback period of approximately 4-5 years.

Environmental Benefits: Significantly reduces carbon emissions, contributing to the national strategy of carbon peak and carbon neutrality.

Social Benefits: As a green and low-carbon application scenario for the Futian District Low-Carbon Supermarket, it has a positive social impact.

Construction Time (Days)

Annual Carbon Reduction (Tons CO₂)

Investment Payback Period (Years)

Green Low-Carbon Technology Promotion Catalog Year

Hu Jianping

Chief Executive Officer of Haylion TechnologiesFounder of eMaaS, Founder and Chairman of Haylion Technologies, Chief Expert of the Urban Passenger Transport Expert Committee of China Road Transport Association, Ph.D. in Road and Traffic Engineering from Tongji University. Previously served as General Manager and Chairman of Shenzhen Bus Group Co., Ltd., Executive Deputy General Manager of Shenzhen Metro Group Co., Ltd., Assistant to Director and Head of Personnel Division of Shenzhen Government Transport Bureau, Vice Chairman of China Road Transport Association, and Senior Vice President of US Microvast Power Systems.

Qiu Jiandong

Senior Engineer of SUTPCDirector of Transportation Information and Model Institute, Shenzhen High-level Talent. 17 years of experience in traffic modeling and big data. Led over 30 urban modeling and big data platform projects and 10 national and provincial research projects. Authorized 30 patents, co-authored 5 monographs and industry standards, published 35 papers, and received 24 national and provincial awards.

Ke Jintao

Assistant Professor of HKUServes as Youth Editor of TRC and Editor of TRE, leading international journals in transportation. Led multiple research projects, including National Natural Science Foundation, Hong Kong Transport Department Smart Transport Fund, Hong Kong Research Grants Council Fund, and Hong Kong Environmental Protection Department Green Fund, with total funding exceeding HKD 10 million. Published over 50 SCI/SSCI papers with over 4,900 citations, recognized as a World Top 2% Scholar in Smart Transportation by Stanford in 2023.